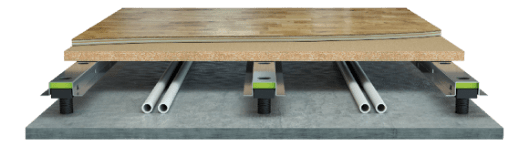

System 9000 – Reliable Planning and Efficient Logistics

Supplied with pre-cut and dimension-adapted floor joists

The system is packaged and delivered with pre-cut and dimension-adapted floor joists and factory-fitted support blocks and damping elements.

Each joist is labelled with a room name and length that match the information in your installation drawing for easy handling and efficient installation.

The system is packaged in bundles on EUR pallets with a maximum length of either 2600 mm or 3800 mm.

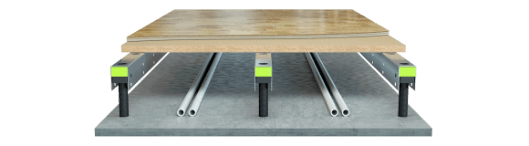

Deliveries during construction

Because the system consists of non-organic materials and is not affected by moisture or temperature variations, it can be delivered while the building structure is still under construction.

Girders produced to a maximum length of 2600mm can be easily delivered and stored with sheets of plasterboard, At the same time, the plasterboard for the walls can be transported in together with the wall studs that are placed on trestles placed over the packaging with studs.

By lifting the materials into place during the construction

of the building structure and erecting the interior walls above the system, production is more efficient and costs for logistics are minimised.

Read more about System 9000N:

Advantages

Data for natural frequency, suspension and step sound improvement

Calculation example

Load Projection

Design of Sylodyn® Pads

Load Plans and Design

Inorganic Materials - No Moisture Impact

Type Approval

Reliable Planning and Efficient Logistics

Our systems

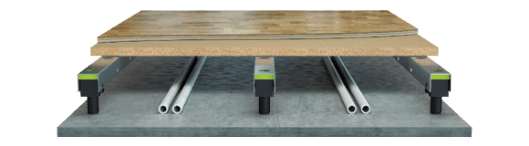

Granab subfloor system 3000N

For adjustable height 30 – 140 mm, excl. Floor covering.

Granab subfloor system 7000N

For adjustable height 70 – 140 mm, excl. Floor covering.

Granab subfloor system 9000N

For adjustable height 70 – 140 mm, excl. Floor covering.