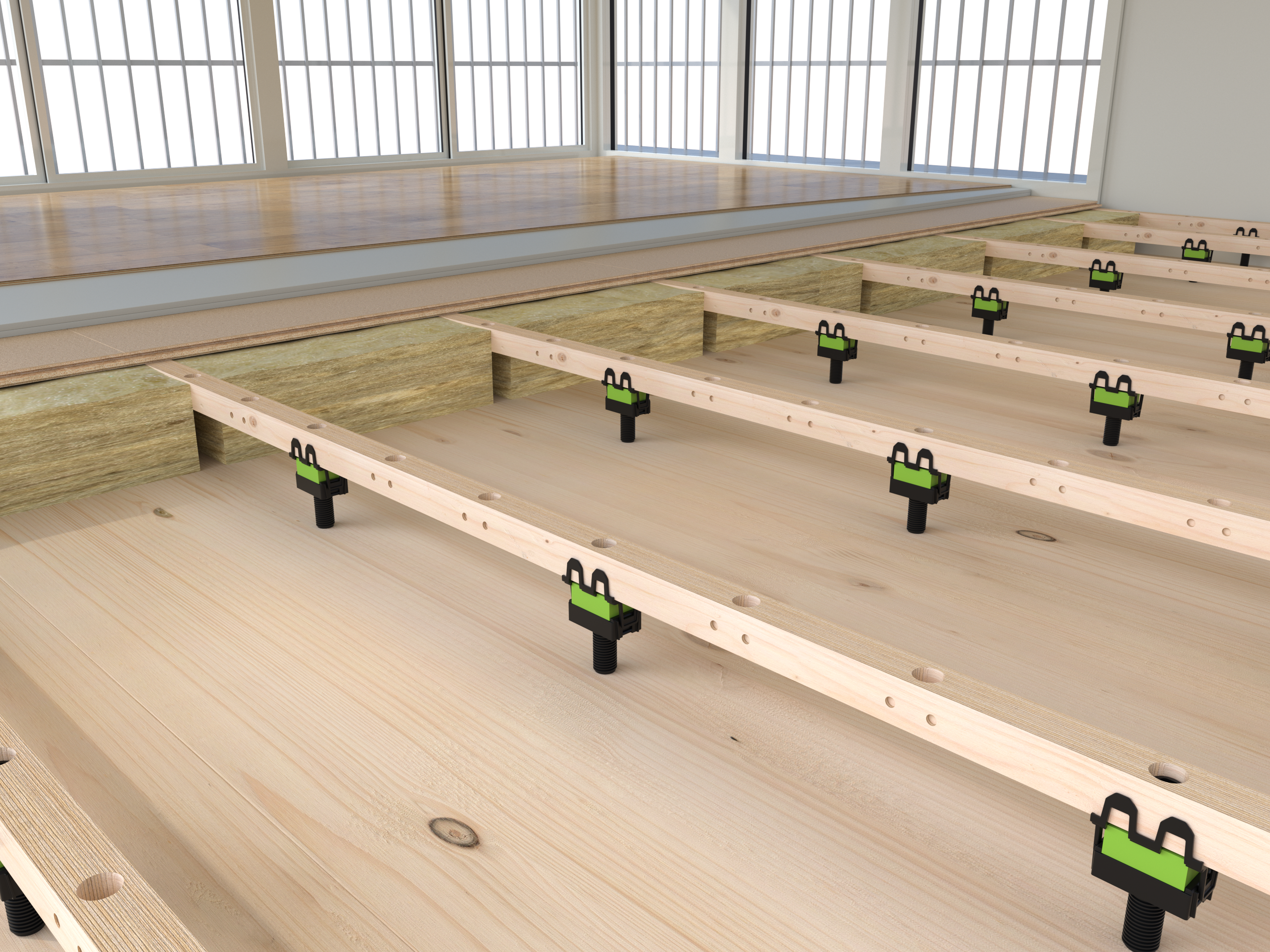

CLT floor with Granab subfloor system

Designing with CLT as a structural material is now a conscious choice – both from a climate perspective and in terms of form. But even the most sustainable material requires the right system solutions to meet high standards for acoustics, flexibility and easy installation.

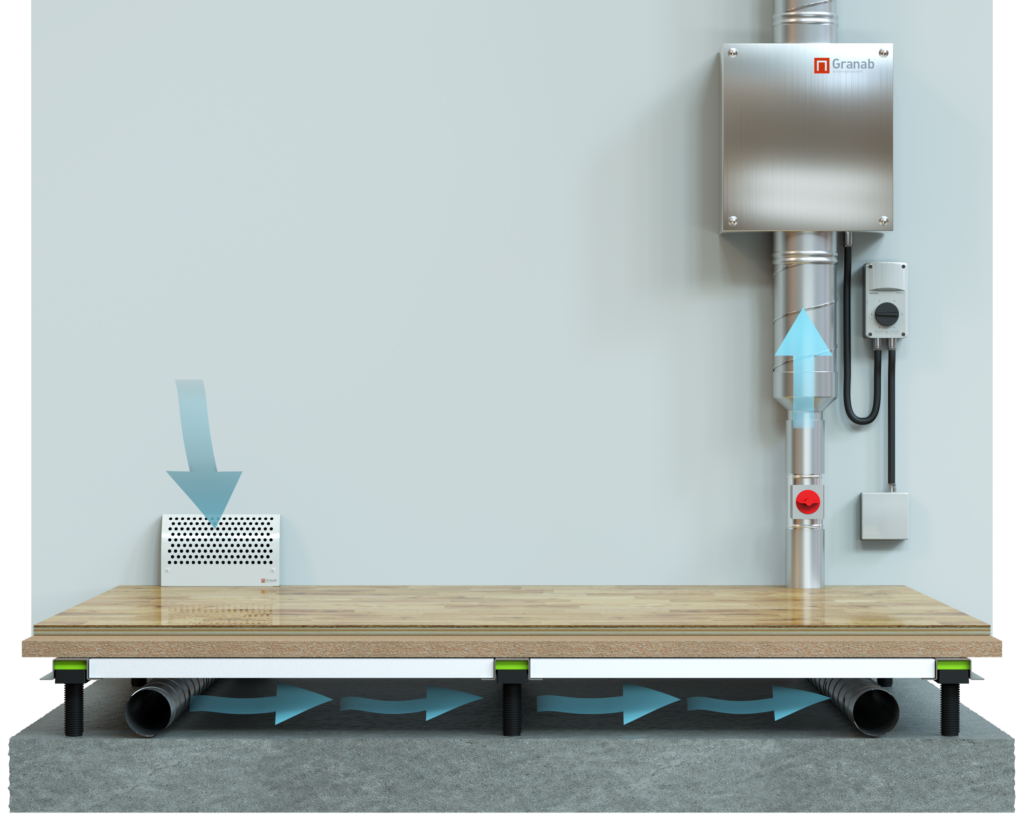

Granab subfloor systems – especially the 8000W and 7000N systems – work very well together with CLT to create quieter and drier wooden buildings.

What is CLT and why is its use increasing?

CLT (Cross-Laminated Timber) consists of cross-glued wooden panels that create a very stable and load-bearing material. It is increasingly used as an alternative to concrete in frames, walls and joists, especially in apartment buildings, schools and public buildings.

The material’s greatest strengths lie in:

- Sustainability and climate performance

- Aesthetic finish – CLT can be left exposed

- Quick and dry installation – thanks to prefabrication

However, CLT also places special demands on floor construction – something that Granab addresses directly.

Challenges in CLT floor structures: installations, moisture and sound

When the floor structure is made of wood, the conditions for installation, soundproofing and climate control change. Three common challenges in architect-led design of CLT buildings are:

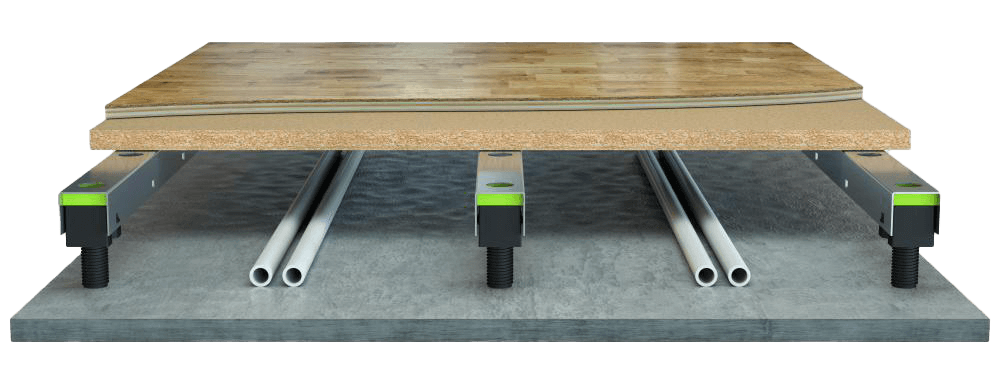

1. Installations

When wooden floor structure are chosen, the preference is often to install all fixtures in the upper floor. This is to avoid the need for a suspended ceiling to cover the fixtures. With Granab, a suspended ceiling is rarely needed to meet sound requirements, and all installations are therefore placed in the upper floor. This offers major advantages both in new construction and in the event of pipe replacements or tenant adaptations, as the installations are located within the apartment/tenant’s area and not in the apartment below.

2. Moisture and indoor environment

Granab can be used to eliminate moisture penetration in moisture-sensitive CLT frames. This is because it eliminates the need for cast-in-place concrete and levelling compound.

This saves a lot of time and significantly reduces the climate impact of the construction project.

Building a house in CLT and then casting the floors takes away the feeling of living in a wooden house. Using comfortable floors from Granab maintains the soft, warm and pleasant feeling of the floor.

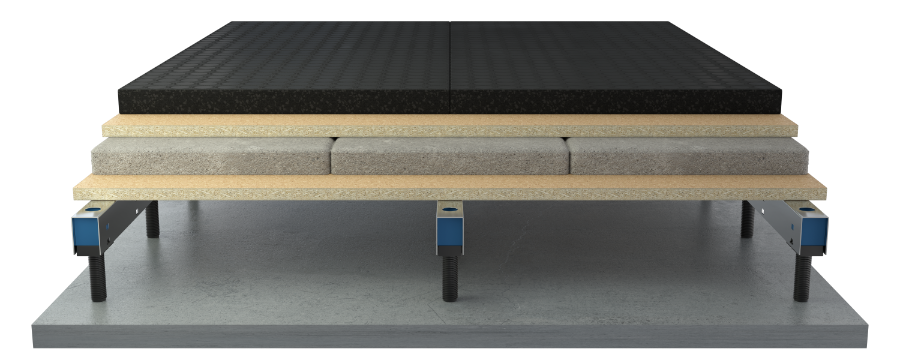

3. Acoustics – impact and airborne sound

Sound transmission between floors in wooden buildings is often an Achilles heel. To achieve sound class B or A according to SS 25267, specially adapted damping solutions are required that work in conjunction with the lightweight wooden floor structure. Read more about acoustics and sound insulation here.

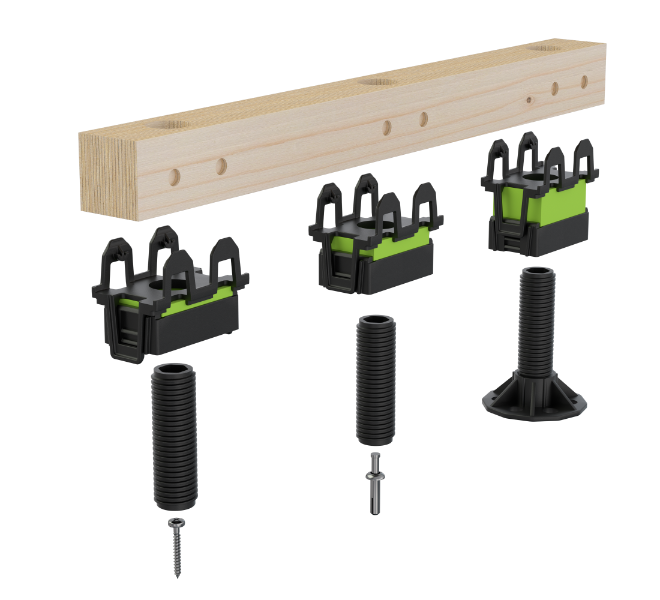

Granab System 8000W – specially developed for CLT

To meet these challenges, Granab has developed System 8000W, a complete subfloor system optimised for use in timber constructions. The system is based on an adjustable wooden beam with Sylodyn damping that effectively reduces sound and handles movements in CLT floors.

System 8000W provides access to:

- Height adjustment between 85–480 mm – for precise floor level and installation space

- Selectable damping elements (6/12/25 mm) – to achieve specific acoustic targets

- Space between floorboards and CLT – which facilitates the installation of fixtures

- Dry installation without concrete or screed – which shortens construction time and simplifies future dismantling

The systems are also documented via EPD, type-approved by RISE and meet the requirements for modern wooden buildings in terms of both performance and environmental profile.

Climate performance and certification value

In combination with CLT, Granab System 8000W offers a documented low climate impact. Through verified EPD, the system has shown 33–65% lower CO₂ emissions compared to conventional concrete-based flooring solutions, depending on the system component and comparison object.

Thanks to the EPD and the product’s circular design, Granab’s system is also relevant for buildings that are environmentally certified according to Miljöbyggnad, BREEAM or LEED. This makes the system a clear contribution to sustainability reporting right from the design stage.

Reference project: Granab in CLT buildings

Several projects have already implemented this combination with good results:

Sävja Trähuset in Uppsala – 2,400 m² of CLT with System 8000W and 25 mm damping elements.

Ripple Residence – a climate-smart building project where Granab’s dry installation facilitated the assembly.

Brf Gourmet – An example where Granab supplied subfloor systems to meet the acoustic requirements when building a frame of CLT, cross-laminated timber.

The next step for your project

Would you like to have a technical dialogue at an early stage, or do you need drawings and performance data to make decisions in your project planning? Contact us today.

Our systems

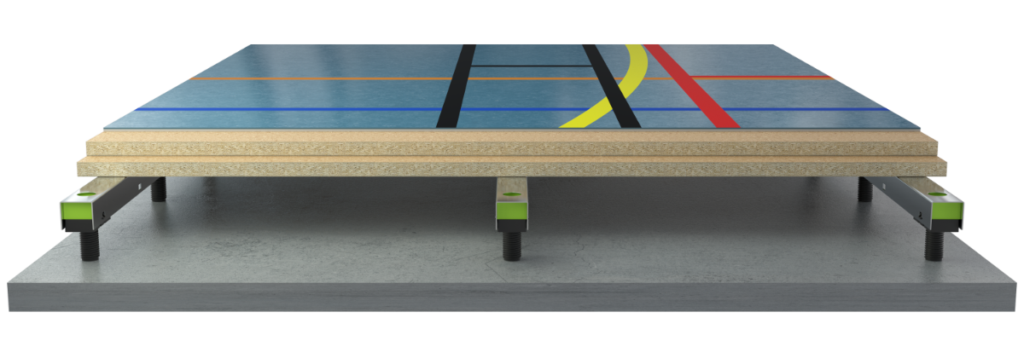

Sports floors

Eight unique Sports floors able to accommodate natural frequencies that are as low as 10Hz.

Read more

Environmental certification

Granab works actively to reduce environmental impact and has certifications that confirm our commitment to sustainability. All our subfloor systems have Environmentally Product Declarations (EPD).